Photolithography (photoresist) material

In the recent rapid progress of manufacturing ultra-fine

semiconductors and flat panels, the processes are

increasingly diversified. The ability to rapidly develop

suitable materials is needed. We are developing a

characteristic photoresists (photosensitive materials) for

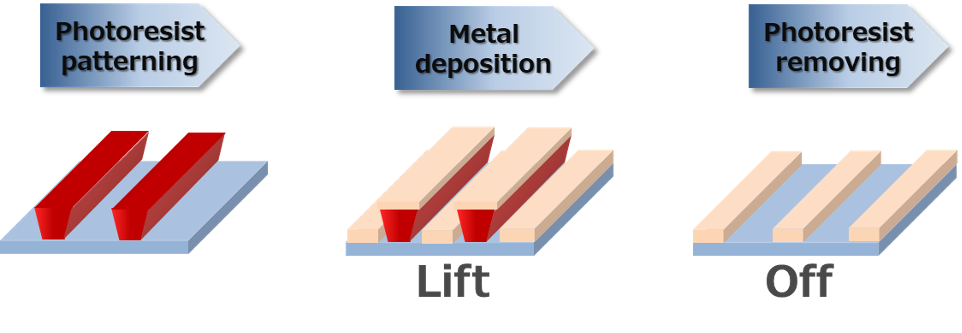

lift-off processing. Lift-off processing has the advantage

of eliminating a metal etching process for wiring, thus

contributing to shortening the process time and reducing the

amount of material used. We also offer consultation on

material development to meet our customers’ individual needs

and detailed requirements. We look forward to hearing from

you through the contact form below.

View

Product Catalog.

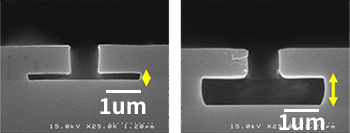

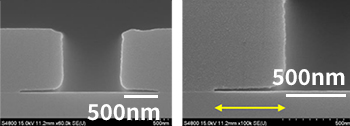

Under Layer Material for Bi-layer Lift-off Processing―BLX Series

- Ideal for a variety of over layer resist applications free of inter-mixing

- Various film thicknesses can be designed for over and under layers

- The amount of side etching can be adjusted as desired depending on the process conditions

- Good easy to be cleaned up

- Possible to replace existing material

- Application examples: Compound semiconductors, optical devices, RF devices, and difficult to etching materials

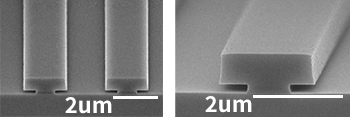

Film thickness adjustment

Adjustments of the amount of side etching in ultra-thin

films

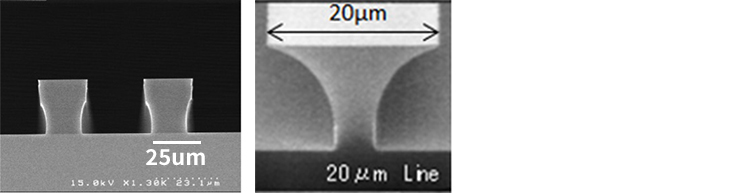

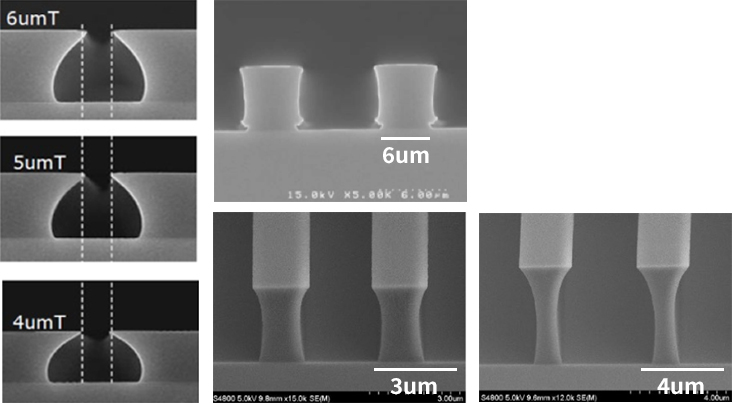

Photoresist for Single Layer Lift-off Processing: NPR9700 Series

- Positive Resist for Lift-off Processing

- Exposure wavelength range: g-line to i-line (broadband compatible)

- Easy to form a anti-taper shape with no special process.

- Good easy to be cleaned up

- We can offer the film thickness, line width, shape, etc., to meet your needs.

- Application examples: Compound semiconductors, optical devices, RF devices, and difficult to etching materials

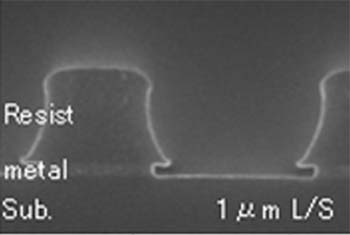

Photoresist for UV Laser Direct Writing―GRX-M Series

-

Ensuring coating performance with a spin coater and

capillary coater used.

Good coating performance on large glass substrates. - Exposure wavelength range: g-line to i-line (broadband compatible) Suitable for laser writing.

- Organic and inorganic alkaline development possible.

- The optimized material composition has improved the in-plane uniformity of line widths on large glass substrates during direct laser writing.

- Improved metal etching performance by optimizing the pattern profile

- Excellent adhesion on the substrate with low side etching.

- Good easy to be cleaned up

- Application examples: Liquid crystal displays and photomask blanks

We are also developing various special resists and photosensitive insulating films. Please feel free to contact us.

Product Catalog

Photolithography (photoresist) material(331KB)

The application examples shown on this website and in catalogs

do not guarantee the application results of our products.

Please evaluate their suitability for your application,

purpose of use, and conditions when using our products.

Furthermore, we do not guarantee that the application examples

presented here are free from infringing any intellectual

property rights.